Summary

In the summer of 2021, Mohammed Biplob, 35, was working at Arefin Enterprise, a shipyard in Chattogram Bangladesh, dismantling a 24-year-old bulk carrier ship called the Max. On August 23, he was torching through a pipe in the engine room when it suddenly exploded. Biplob said the explosion threw him against the wall, severely burning his face and breaking his back. He lost consciousness, only becoming alert when he realized his coworkers were carrying him to the road. He said at the time he could see what was happening but couldn’t speak. Biplob’s family sold all their land to pay for his continued medical treatment and he now runs a tea stall to support them.

Arefin Enterprise is just one of about 30 yards currently actively operating in Bangladesh where workers break down the world’s ships once they are no longer seaworthy. Companies like Arefin Enterprise purchase end-of-life ships, take them apart, and sell the metal and other materials after the ship is dismantled. Shipbreaking is an extremely lucrative industry for Bangladesh, contributing an estimated $2 billion to the country’s economy. More than half of the steel used in Bangladesh comes from ships broken down in Chattogram.

However, the industry in Bangladesh is highly dangerous and unregulated. Biplob explained that some regulations that could have prevented his injury were not followed. For instance, he said nobody checked the pipe, which had apparently been full of octane, to see whether it was “gas-free for hot work” as is required by Bangladesh law. Arefin Enterprise paid for Biplob’s 8-day emergency treatment and about US$160 in compensation—far less than the nearly $2,000 he was owed under Bangladesh law. But Biplob said the owner of the Max should also be held responsible.[1]

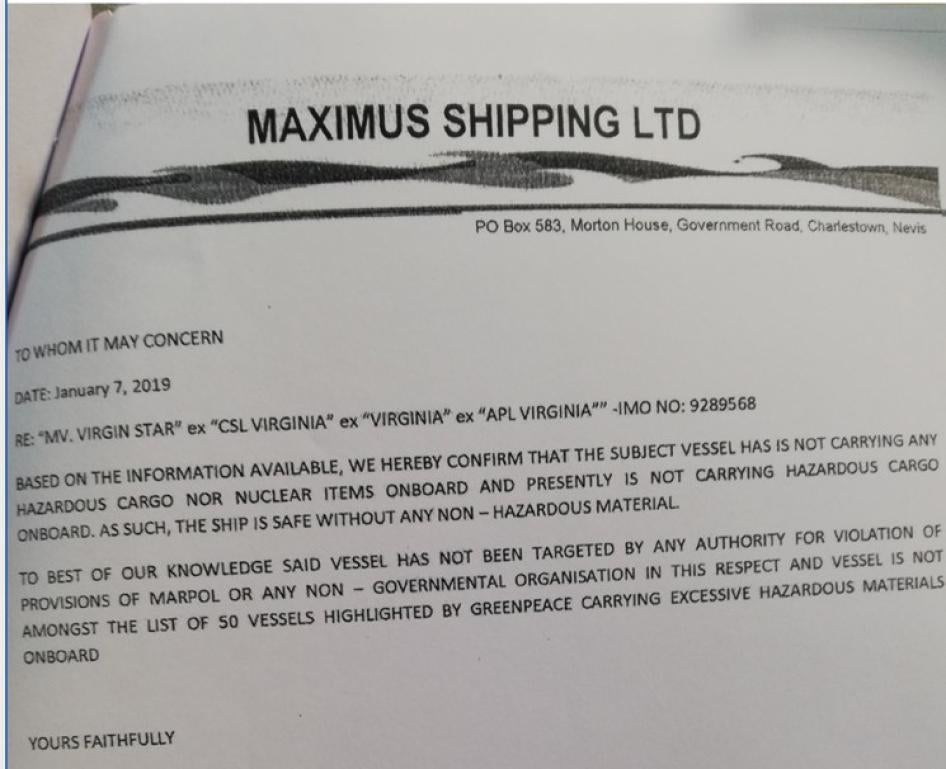

The Max was previously owned by Greek shipping company Tide Line Inc. and never should have been in Bangladesh in the first place.[2] International and regional laws prohibit the export of ships to places like the yards in Bangladesh that do not have adequate environmental or labor protections to prevent accidents like the one that injured Biplob. Yet neither international law nor repeated injuries and deaths of workers have deterred many shipping companies from dumping their ships in Bangladesh. Instead, they have simply found ways to circumvent regulations and avoid culpability. As one Bangladeshi activist said, “There are legal regulations, but there are also loopholes.”

The Max should have been subject to European Union (EU) regulations regarding the disposal of end-of-life ships. The European Union Waste Shipment Regulation (EUWSR) prohibits the shipment of waste—including end-of-life ships like the Max—from EU waters to non-OECD (Organization for Economic Cooperation and Development) countries like Bangladesh. Additionally, as of December 31, 2018, the EU required all EU-flagged ships to be recycled at an EU-approved facility that is regularly and independently audited for compliance with standards on environmental protection and workers’ safety. None of the yards in Bangladesh have been approved by the EU commission audit.

However, Tide Line Inc, like many European shipping companies, avoided these regulations by selling the Max to a scrap dealer before it was declared waste and sent on its final voyage. The Max's new owner, known as a “cash buyer” because of the money they pay for end-of-life ships, then ensured the Max was out of EU waters and operating under a non-EU Comoros flag when sent for scrapping.[3]

The EU Ship Recycling Regulation (SRR) only applies to ships flagged by an EU state, which allows companies to avoid the EU requirements by transferring a ship’s flag to a different state, known as a “flag of convenience.” Flags of convenience are sold by flag registries which, in many cases, are private companies operating in a different country from their flag state. As Ingvild Jenssen, executive director and founder of the NGO Shipbreaking Platform, said in a 2022 report:

The decisions to scrap these ships under conditions that would not be allowed in the EU are taken in offices in Hamburg, Athens, Antwerp, Copenhagen and other EU shipping hubs. This reality begs for the introduction and enforcement of measures that effectively hold the real beneficial owners of the vessels responsible, regardless of the flags used and/or of the ports of departure.

The Max was sold by Tide Line Inc. to a cash buyer in June 2021 and was approved for import to Bangladesh for scrap later than month. It reached Chittagong in Bangladesh on July 10, 2021. The explosion that injured Biplob occurred just over a month later.

The fact that Tide Line Inc., the exporting port, and the scrap dealers who directly sold the ship to Arefin Enterprise could all evade liability for Biplob’s injury is common. Hundreds have been injured or killed over the last decade in Bangladeshi shipbreaking yards with little recourse or systemic reform. Written in partnership with the NGO Shipbreaking Platform, this report documents the abusive practices in the shipbreaking industry in Bangladesh and maps out the actors, policies, and loopholes, that enable these abuses.

Though most ships were originally owned by European, East Asian, and Southeast Asian companies, the final destination for over 80 percent of all end-of-life ship tonnage is one of three beaches in South Asia: Chattogram in Bangladesh, Alang in India, and Gadani in Pakistan. By cutting costs on safety, labor, and environmental protections, many of these South Asian yards offer to buy end-of-life ships at more than double the price of their next closest competitors in Turkey.

Bangladesh, in particular, is a top destination for end-of-life ships. Since 2020, approximately 20,000 Bangladeshi workers—many of whom are children—tore apart more than 520 ships, totaling far more tonnage than any other country in the world.

Dangerous Work Conditions

Higher profits for shipping companies come at a fatal price. Many Bangladeshi shipbreaking yards often cut costs through shortcuts on occupational and safety measures, dumping toxic waste directly onto the beach instead of using an adequate facility, conducting illegal and dangerous night shifts, and denying workers living wages, rest, or compensation in case of injuries. Workers and surrounding communities are frequently exposed to toxic materials in the air they breathe, the water they drink, and the food they grow and eat, impacting health and livelihood.

The International Labour Organization (ILO) has described shipbreaking as one of the most dangerous jobs in the world. Workers told Human Rights Watch how their legs were cut off by falling iron, how they fell from multiple stories, or were trapped inside a ship when it caught fire or pipes exploded. Lack of protective equipment and accessible emergency medical care at shipyards meant that, in many cases, workers were forced to carry their injured coworkers from the beach to the road and find a taxi or rickshaw to a hospital. “They threw me away,” said Masum, 44, who lost his leg after a pipe he was cutting exploded and the yard owner tossed him on the bed of a truck outside the yard rather than taking him to the hospital. In Bangladesh, the life expectancy for men in the shipbreaking industry is 20 years lower than the average.

Ships contain toxic materials such as asbestos, heavy metals, oil, and toxic paints and compounds. In many cases these hazardous substances are not properly identified despite international requirements to include an Inventory of Hazardous Materials (IHM). Workers are thus exposed to toxic fumes and materials without necessary protections. A 2017 study by the Bangladesh Occupational Safety, Health, and Environment Foundation found that more than one third of the shipbreaking workers surveyed suffered preventable health complications from asbestos exposure.

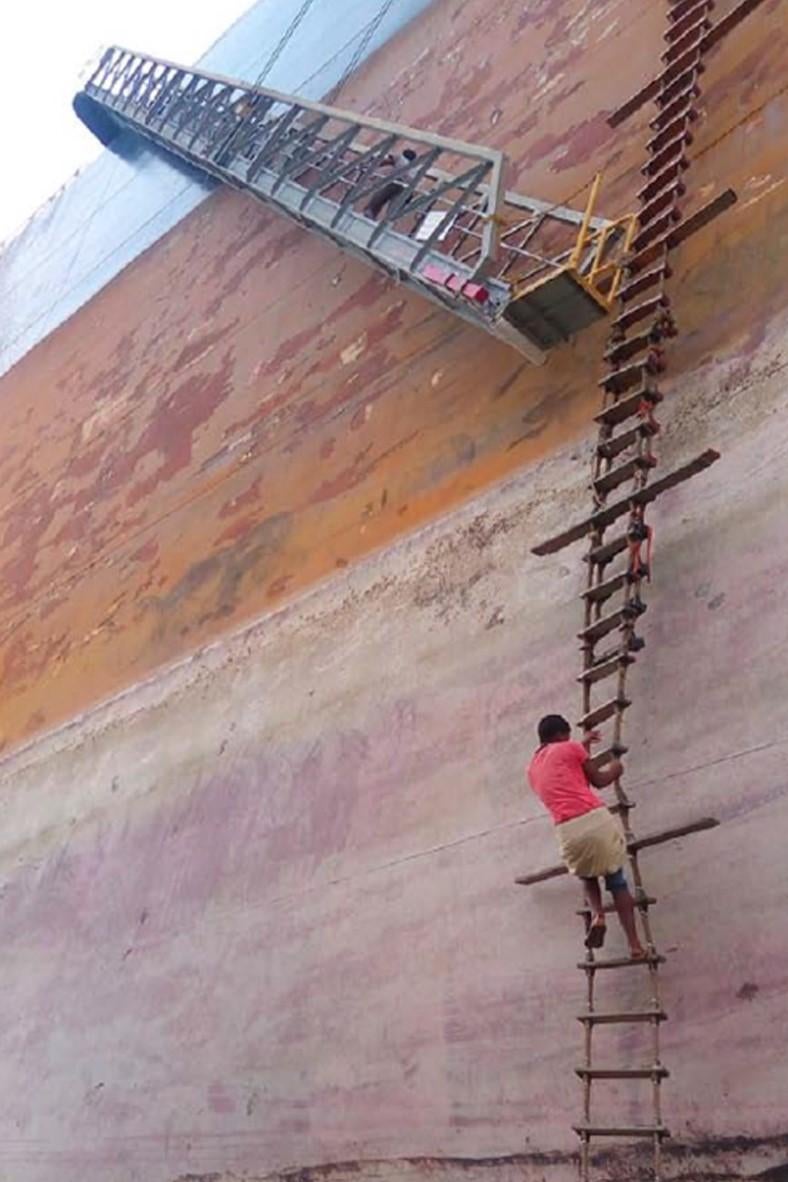

Shipbreaking workers in Bangladesh interviewed by Human Rights Watch consistently said that they were not provided with adequate protective equipment, training, or tools to safely do their jobs. Workers described using their own socks as gloves to avoid burning their hands as they cut through molten steel, wrapping their shirts around their mouths to avoid inhaling toxic fumes, and carrying chunks of steel while barefoot.

In violation of Bangladesh labor laws, shipbreaking workers interviewed by Human Rights Watch say that they are often denied breaks or sick leave, even when they are injured on the job. In most cases, workers are paid a fraction of what they are legally entitled to under Bangladesh’s minimum wage regulations for shipbreaking workers. Typically employed temporarily, workers are rarely given formal contracts, leaving them with few means to advocate for their rights. Some workers said they were made to sign what they were told were contracts that they were not allowed to read or retain. Others said they were simply made to sign a blank piece of paper. The informal nature of the industry means that yard owners can cover up worker deaths and injuries, in some cases denying that a worker who died on the job had ever worked there. When workers attempt to unionize or protest conditions, they are fired and harassed. Tanvir, 50, a shipbreaking worker who has been in the industry since 1982 said,

While working in this industry I saw so many of my colleagues lose their lives. But still the system never changed. Workers’ rights are violated every day. I think shipbreaking is the most neglected industry in the world.

Beaching Toxic Ships on Bangladesh Shores

Shipyards in Bangladesh use a method called ‘beaching’ in which ships sail full steam onto the beach during high tide to be taken apart directly on the sand instead of using a dock or contained platform. Beaching is inherently more dangerous for workers. Since the work is done directly on the sand, the worksite itself is full of hazards. As one worker, Golam, 32, explained:

There is no safety for the workers because everywhere there are iron plates and rods around and there are muddy and slippery walking paths so we cannot move easily, and we are always in danger.

It is difficult, if not impossible, for emergency vehicles to traverse the sandy beach to access the job sites in case of injuries or fire. All the workers interviewed for this report who were injured on the job had to be carried to the road by their colleagues before being taken in a privately owned vehicle to receive emergency medical treatment.

Beaching is also environmentally damaging. Toxic chemicals, oil, and other pollutants are dumped straight onto the sand and the sea while gasses and dangerous particles pollute the air. Heavy metals and other pollutants poison the soil, water, and nearby agriculture and permanently impact marine biodiversity and coastal habitats. According to the Marine Institute of the University of Chittagong, the Bangladesh shipbreaking industry has wiped out 21 species of fish and crustacean and endangered 11 other species.

Pollution from shipbreaking appears to also impact the livelihoods of surrounding fishing communities. Sohel, 28, who used to fish for a living but started shipbreaking because fishing became unfeasible, told Human Rights Watch that:

The poisonous chemicals and fuel from the ships are going into the sea waters and the fish are dying... Dead fish are flooding the shores.

Despite importing so much of the world’s waste, Bangladesh has no toxic waste processing facility. The Bangladesh Ship Reprocessing Act, passed in February 2018, declared that by February 2021 the government would establish a Waste Treatment Storage and Disposal Facility for toxic waste from ship recycling. However, at time of writing, over two years past the deadline, no such facility has been created and toxic waste continues to be dumped straight on the beach, putting the lives and livelihoods of the surrounding communities at risk, and exacerbating environmental degradation. Toxic asbestos is sold directly in the marketplace in what locals call “asbestos villages,” where stoves and other furniture made from scrapped asbestos are sold.

Ship recycling does not need to be this dangerous or environmentally damaging. There are safe and sustainable alternatives. In particular, the use of a stable platform—called dry-docking[4] or pier-breaking[5]—is much safer than beaching, because it allows for the use of lifting equipment and cranes, makes the site accessible in case of emergency, and makes it easier to safely contain and manage toxic waste and other hazardous materials. There are dozens of ship recycling yards, primarily based in Europe, that safely recycle ships using environmentally sustainable practices.

The NGO Shipbreaking Platform estimates that the entire shipbreaking industry worldwide could feasibly transition to dry-docks by 2030. But alternatives like dry-docking cost more, as do facilities for safe disposal of toxic waste, training, safety equipment, fair wages, and insurance for worker injuries and deaths.

The Role of the International Shipping Industry

An entire industry exists to enable shipowners to circumvent international regulations so that shipping companies can continue to cheaply discard ships in Bangladesh’s dangerous yards.

To avoid international, regional, and domestic laws, companies can sell the ship to a cash buyer, who serves as a scrap dealer for end-of-life ships. In many cases, the cash buyer will use a shell company as the new registered owner of the ship during its sale to scrapyards in Bangladesh, making it difficult to track the ship’s true beneficial owner. The cash buyer then registers the ship under a flag from a state with lower regulatory burdens—called flags of convenience.

Shipping companies frequently use flags of convenience throughout a ship’s operation to circumvent regulations, including labor rights at sea. But they are especially common at end-of-life when a company is scrapping a ship in South Asia. In 2022, while over 30 percent of the world’s fleet was owned by European companies, less than 5 percent had an EU flag when they were sold for scrap. Publicly available shipping records indicate that all ships with beneficial owners based in the EU, the US, or UK scrapped in Bangladesh over the last four years entered Bangladesh waters under a flag of convenience.[6]

A lack of enforcement of international laws and regulatory standards further enables ships to be scrapped under dangerous and environmentally damaging conditions. Exporting countries outright ignore the requirements under the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal (the Basel Convention) to obtain prior informed consent from the importing country and to ensure that end-of-life ships are only sent to countries with sufficient capacity for environmentally sustainable management of toxic waste. On the import side, Bangladesh shipbreaking yards avoid scrutiny under national laws by outsourcing inspection reports and required documentation to cash buyers and other unscrupulous middlemen. Waste declarations for ships imported to Bangladesh are often completed without any oversight, transparency, or clear accreditation, with potentially fatal consequences.

The International Maritime Organization (IMO) is the UN entity responsible for regulating and enforcing international shipping standards, including environmental and labor protections, and has the authority to enforce these requirements. However, the structure of the IMO limits its ability to act as an effective regulator. Decisions at the IMO enter into force when a certain number of states that represent a certain percentage of the world fleet have ratified. Since flags of convenience are up for sale, countries that flag more ships have more influence at the IMO, and also have the greatest incentive to keep regulatory burdens low.

On June 26, 2023, Bangladesh and Liberia acceded to the IMO’s Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, 2009 (the Hong Kong Convention), thus meeting the requirements for the convention to enter into force on June 26, 2025. In a letter to Human Rights Watch, an IMO official said that the Hong Kong Convention is “making a positive contribution in regards of the right of workers to a safe and clean working environment.” However, while the IMO, shipping companies, and shipbreaking yards promote the Hong Kong Convention as the solution to a safe and sustainable ship recycling industry, experts and activists have long-lamented major gaps in the convention that weaken its ability to provide the level of regulation that its proponents promise. Experts have repeatedly raised concerns that the Hong Kong Convention will serve to greenwash the shipbreaking industry, without ensuring much-needed regulation. At the same time, exporting countries continue to ignore the Basel Convention, which applies to end-of-life ships, and offers a higher level of control than the Hong Kong Convention.

Bangladeshis should not suffer the environmental and health impact of dismantling toxic ships under unsafe conditions simply because their lives are considered cheaper. Instead of investing time and resources in greenwashing unsafe practices, companies should invest in proven methods and they should stop insisting that beaching is safe. To ensure global capacity to sustainably recycle the massive influx in end-of-life ships over the next decade, shipping companies should invest in building stable platform facilities at a standard that fully protects workers’ rights and include mechanisms for the downstream management of waste.

Existing international and domestic regulations do not go far enough and, in some cases, are designed to be ignored. To ensure workers are protected, laws prohibiting the sale of end-of-life ships to yards without adequate safety and environmental measures should apply to the country of the ship’s beneficial owner, including for at least two years after its sale; shipping companies should face economic costs for circumventing regulations; exporting countries should adhere to the requirements set out in the Basel Convention and the Basel Ban Amendment; and cash buyers and other intermediaries should be properly regulated.

Key Recommendations

To the Government of Bangladesh:

- Fully enforce the High Court’s 18-point directive that requires rigorous health and safety standards and labor rights protections in shipbreaking yards.

- Immediately shut down any shipbreaking yards employing children and/or holding night operations or where there are other serious violations of workers’ rights.

- Adequately compensate all workers who have been injured (or, in the case of death, their families), as provided under the Labour Act, 2006 and the Shipbreaking and Recycling Rules, 2011.

- Move all ship recycling operations off the beach and to proper industrial platforms in accordance with the Basel Convention Technical Guidelines on Ship Recycling to ensure full containment of pollutants.

- Build a functioning hazardous waste storage and disposal facility that meets international standards for the management of toxic waste from shipbreaking.

To the European Commission:

- As part of the 2023/24 review, amend the EU Ship Recycling Regulation (SRR) to apply to the ship’s beneficial owner, not the flag state. If the ship is sold, the regulation should remain applicable to the previous owner for no less than two years from the date of sale.

- Include in the revised regulation a “return-scheme” for ships as described in the EU SRR preamble. The return scheme would require any ship that trades in EU waters to pay a fee towards a recycling license, accumulating capital over time. The total will then only be paid back to the last owner of the vessel if the ship is recycled at an EU-approved facility.

- Require all shipping companies conducting operations in the EU to implement a risk-based approach due diligence policy on their whole value-chain in line with the UN Guiding Principles on Business and Human Rights (UNGP), recognizing shipbreaking as a high-risk business operation, and to publicly report all sales, including to cash buyers, to ensure the traceability of the ship’s beneficial ownership over its lifetime.

- Ensure that the proposed EU Corporate Sustainability Due Diligence Directive (CSDDD) covers the full value chain, including the use, disposal, and recycling of goods.

To Shipping Companies:

- In line with the UNGP and with the upcoming CSDDD, adopt formal and explicit policies that ensure the company maintains oversight of where ships are recycled and ensures that ships are not discarded in yards that use the beaching method and/or violate labor rights.

- Invest in ship recycling facilities so that they can ensure full containment of environmental contaminants, stable industrial platforms, protective equipment, and environmentally sound management of hazardous materials, including disposal.

Methodology

This report is produced in collaboration with the NGO Shipbreaking Platform which provided expert analysis and additional investigations tracking ship movements and transactions.

The report is based on Human Rights Watch interviews with 45 shipbreaking workers and relatives of shipbreaking workers. We also interviewed 2 doctors working in Chattogram and 8 experts on shipbreaking, ship recycling, and Bangladesh environmental and labor laws.

All workers interviewed provided verbal informed consent to participate and were assured that they could end the interview at any time or decline to answer any questions. No compensation was provided for any interviews. Most workers quoted in this report have been given pseudonyms and, in some cases, other identifying information has been withheld to protect them from retaliation.

The report also relies heavily on analysis of primary data sources including public shipping databases, company financial reports and websites, Bangladesh maritime import records, and leaked import certificates.

Human Rights Watch wrote to 12 shipping or shipbreaking broker companies, 6 flag agencies and 3 shipbreaking yards as well as to the International Maritime Organization, and the Bangladesh Department of Environment, the Ministry of Industries, the Ministry of Labour and Employment, and the Bangladesh Ship Recycling Board.

Human Rights Watch received replies from A.P. Moller – Maersk A/S on May 29, 2023, Best Oasis Ltd on June 1, 2023, the International Maritime Organization on June 29, 2023, and Novonor on July 3, 2023.

These letters and replies are included in appendices I-VII, except for the reply from Best Oasis which the company requested we do not include for publication.

I. Dangers of Shipbreaking in Bangladesh

Labor in Bangladesh’s shipbreaking industry is largely informal, unregulated, and rarely subject to occupational health and safety inspections or controls. Workers in many Bangladesh shipbreaking yards cut wires and pipes, blast through ship hulls with blowtorches, climb multiple stories, and haul scrap metal, often without adequate protective gear. Many are killed and seriously injured by explosions, are crushed by falling chunks of steel, and are burned by flammable gases, liquids, and other materials in the ships.

Workers persistently described feeling afraid for their lives when they went to work. Abul, 31, said: “If I am distracted for even a moment in the place where I work, I could die immediately.”[7] Another worker, Kamrul, 39, who has worked in shipbreaking for 27 years since he was 12 years old, said that injuries in the yards are common. “We are not safe in the shipyard while working,” he said. “Nails hit us, or flames hit us. Most of the workers at some point get burned. I never feel safe.”[8] Sabbir, 27, who has been working in the yards for seven years, said he doesn’t want to work in shipbreaking because it is too dangerous but feels he has no other options. “Nobody wants to work here because they know there is a risk and accidents may occur at every step,” he said. “The owners do not provide us with any safety measures. They overlook these things.”[9] During a November 2022 visit, the Independent Expert on the enjoyment of all human rights by older persons, Claudia Mahler, noted that “while accidents regularly happen, sometimes leading to death, no statistical data on deaths and disabilities caused by accidents is collected.”[10]

Many shipbreaking workers are children. A 2019 survey of shipbreaking workers estimated that 13 percent of the workforce are children.[11] Researchers noted, however, that this number jumps to 20 percent during illegal night shifts.[12] Many of the workers interviewed for this report began working as children, around 13 years old.

Lack of Occupational Safety and Hazard Protections

Once ashore, the shipbreaking process is done in two stages: cutting and carrying. In the cutting stage, workers (“cutters” and “helpers”) dismantle the ship by hand and with oxygen-acetylene or liquefied petroleum gas (LPG) torches. Injuries linked to this phase are frequently caused by fires, or explosions, and falling or being crushed by falling metal. In the carrying stage, workers (“carriers”) drag steel and other parts ashore piece by piece. Carriers often lack adequate equipment including steel-toed boots or gloves. Instead, carriers in some cases are working barefoot, carrying chunks of steel over the sand. Repeated heavy lifting without adequate training or tools can cause serious injury.[13] In other cases, carriers use three-wheelers or other small vehicles to pull heavier chunks that can weigh up to a thousand tons.[14]

Failure to safely manage flammable substances

Ships are full of flammable substances such as diesel, oil, gas, oxygen tanks, and polymers. According to the Basel Convention Technical Guidelines and the Bangladesh government 2011 Shipbreaking and Recycling Rules (further discussed in Section II), the vessel should be secured before any cutting begins, all flammable substances should be either safely removed or secured, and precautions should be in place.[15] But many shipyards in Bangladesh rarely conduct adequate inventories of material on the ship before the cutting begins, leaving workers at risk of serious burns, death, or injury from explosions.

Syed, 22, who works as a cutter, said: “We cut the ship using oxygen and LPG gas torches. When we cut a tanker or oil line of the ship, there is always a high risk of explosion. We work knowing that at any time a fire incident can take place.”[16] Ahmed, 26, who also works as a cutter said: “We feel afraid while cutting the oil pipeline because sometimes sparks from our torches create fire which can easily burn a cutter man.”[17]

Workers are also at risk of falling from the ship or can be crushed by falling chunks of steel or other parts. “The ship is big. We cut the ship while hanging off the side using a rope ladder. Workers sometimes slip and fall into the water,” Ahmed said.[18] Hasan, 25, who worked as a cutter, said he left the job in April 2021 after he fell from the second floor of a ship:

The ship was a container ship, so it already had crane installed in it with a ladder to the edge of the crane. While I was climbing the ladder to remove the crane, the ladder slipped. I did not have any safety harnesses, so I fell about 4.5 meters to the ground floor.[19]

Hasan received 15 stitches in his head and said the doctor told him his skull was fractured and that it would take two months to fully recover. When we interviewed him eight months later he said he still has severe headaches: “I feel pain. Whenever I hear any sound, it affects me and my brain badly.”[20] He explained that while he was in the hospital the yard did not pay his wages. The yard paid for five days in hospital but nothing afterwards.

Failure to provide adequate protective equipment

According to the 2011 Shipbreaking and Recycling Rules, all shipbreaking workers must be provided with protective equipment “including head protection, face and eye protection; respiratory protective equipment; hearing protection; protectors against radioactive contamination; protection from falls and appropriate clothing.”[21] But workers in Bangladesh report that they rarely have adequate equipment, putting them at risk of serious injury and death. Ahmed, 26, a cutter, explained:

The company provides very low standard gloves. They are supposed to give us two pairs of gloves every 15 days, but we only get one. They give us some safety gear, but it is very low quality. They never give safety goggles, which are essential since the sparks of fire from cutting the iron are very dangerous and there are so many cases where workers get eye injuries.[22]

Mizanur, 38, a cutter who has worked in the shipbreaking yards since he was 18, said that the safety gear provided is of “very low quality. It doesn't fit on our bodies. The glasses fall right off,” he said.[23] Abul, another worker, said:

I am not convinced the safety gear provided by the yard authority is adequate. If they would give us proper equipment, then it would be easier for us to work. The company gave us helmets, gumboots, gloves, and glasses which are all low quality. Even when the yard authorities provide us with this safety equipment, they take the money from our wages. Otherwise, we buy safety equipment ourselves. The gloves are so low quality that sometimes they get burned by the sparks of fire. The work we do here is really dangerous, but we do not have other options.[24]

Syed, 22, said that he and his coworkers get gloves once a week, but the gloves are such poor quality they are unusable within three days. “When the gloves do not work anymore, sometimes we use socks to protect our hands from the flame,” he said. He also said that the protective eyewear is inadequate: “The safety goggles that they give us to protect our faces while cutting with fire does not work properly after three days. It becomes blurry. The glasses costs only BDT30 [$0.35] but we have to wait 10 to 15 days for new ones so sometimes we don’t wait for the owner, we buy it ourselves.”[25] Syed makes BDT 585 per day ($6.82).

Workers say that if they complain about the lack of protective equipment, they are told they can quit. Asif, 25, who has been working as a cutter for seven years, said that the yard he works in does not provide any protective gear at all. He said “If I go to the office and ask for gloves or mask, the company refuses and says if you want to work, then work without gear. Otherwise leave the yard.”[26]

All the workers interviewed for this report said most yards sometimes provide the cutters with limited protective equipment, but helpers and carriers get nothing. Ahmed explained that gloves and goggles are not provided at all to the helper who works with him. He said that when his helper is lifting heavy objects, he lends him his own gloves. “Gloves are so important for the helper job because the sheets of iron and ship pieces are so hot when they are cut, it is very important to wear gloves, but the company never provides gloves,” he said.[27] He said he also bought his helper protective eyewear from the market, though Ahmed makes BDT 550 (US$6.40) per day.

Carriers lift heavy loads and risk severe injuries, particularly because the beaching method makes safer transportation impossible. Sohrab, 27, has worked in one yard for eight years as a carrier. His job is to carry oxygen cylinders weighing about 120 kg each (260 lbs) from the ship to the shore. He said the yard provides no protective equipment to carriers—even boots—and so he works barefoot. He earns 200 BDT ($2) per day and says he cannot afford to buy his own gumboots. He said:

I only make 200 taka per day so I cannot afford gumboots that cost 800 taka. I work barefoot. This is why workers often get injured with fire or wire or nails stabbing into our feet. the company provides nothing for our safety. If I ask for safety equipment, the company owners say “if you have a problem then leave.”[28]

Lack of access to emergency medical care

Bangladesh’s 2011 Ship Breaking and Recycling Rules require that shipbreaking yards have dedicated and accessible health facilities with an “adequate number of beds for a trauma unit, orthopedic unit, burn unit, intensive care unit, other chronic diseases, and disabilities treatment unit.”[29] While, there is a healthcare clinic run by the Bangladesh Ship Recycling Board (BSRB), it only has facilities to treat primary injuries. In the case of any major injury, workers need to be transported either to a private clinic or, more often, the government-run Chattogram Medical College Hospital.

The shipbreaking rules also require accessibility for ambulances and other emergency vehicles. But because shipbreaking in Bangladesh is done on the sand, it is nearly impossible for emergency vehicles, even if they are available, to get to the work site. After an explosion on a ship in 2019, for example, video footage shows barefoot workers without any emergency equipment carrying their injured colleagues.[30] In every case of injury documented in this report, injured workers said their colleagues had to carry them from the worksite to the road, in most cases without a stretcher. Once they reached the road, in most cases, they had to hire a rickshaw, car, or “CNG” (motorized rickshaw) to get to the hospital.

Nurul, 24, who had been working in shipbreaking yards since he was 14, suffered severe injuries to his spinal cord on April 27, 2022, when a heavy piece of iron fell over two meters and hit him on the back. He said his coworkers carried him to the car because there was no stretcher and eventually the yard owner hired a private car where he rode in the backseat to the hospital, potentially exacerbating his spinal cord injuries.[31]

On November 19, 2017, during an illegal night shift at around midnight, Rakib, 20, was cutting a heavy piece of iron when the piece fell, chopping off his left leg, while an iron rod pierced his stomach. He was pinned to the ground for 45 minutes before other workers were able to rescue him. Because he was working in the middle of the night, there were no cars or rikshaws immediately available to transport him to the hospital, so his coworkers carried him on their shoulders to the nearest clinic. The clinic refused to take him, saying they didn’t have the capacity to treat injuries so severe, at which point they were finally able to hire a private car to take him to Chittagong Medical College where he underwent treatment for 17 days.[32]

Some workers said shipyard owners delayed their transport to the hospital by refusing to pay for transportation costs. Omar, 30, said he was injured in January 2018 when a heavy piece of iron landed on his leg. He said the owners refused to help transfer him to emergency care and it took about eight hours before he was able to get a vehicle to the hospital.[33] Masum, 44, said that on December 12, 2018, he was cutting through a pipe at a steel rolling mill when it exploded. He said workers helped carry him to the road, but the owner just tossed him on the bed of a truck outside the yard. “They just threw me away,” he said. He said his coworkers called his brother who came and took him to the hospital where his leg was ultimately amputated.[34]

When Aarul, 39, fell 6 meters from a ship, he landed on scattered pieces of iron that fractured his leg and knocked out five teeth. Instead of taking him to the hospital, however, the yard managers took him to his room and left him there. He said he was in severe pain, so he called a worker who helps advocate for other workers’ rights who went and confronted the shipyard owner. The owner finally agreed to take Aarul to the BSRB hospital where he received treatment for four days. He was out of work for about eight months without wages and he is working in another shipbreaking yard now. He said, “It feels risky because I know there is no safety for the workers anywhere in this sector. But I have to keep working in the yards because if I stay at home who will give me food?”[35]

During her 2022 visit, Independent Expert on the enjoyment of all human rights by older persons, Claudia Mahler, similarly noted that older workers are frequently not provided with adequate protection equipment and have limited access to healthcare and social protection.[36]

Refusing to provide medical care, compensation

The 2011 Shipbreaking and Recycling Rules as well as the 2006 Labour Act require employers to pay for treatment of workplace injuries, to cover wages up to a year during recovery, and to pay compensation in case of injury or death, including for longer-term health impacts such as asbestosis and cancer. Under the 2011 Shipbreaking and Recycling Rules, after an accident, a yard is supposed to immediately suspend operations for a week while the Bangladesh Ship Recycling Board conducts an independent investigation and mandates any necessary changes. In case of injury, the board is supposed to initiate penal action and, in the case of negligence, suspend yard operations for a year and mandate payment of about $1,800 to injured workers alongside coverage of complete treatment and up to one year’s worth of wages. The compensation for fatality is $4,500.[37]

However, these measures are rarely taken, and workers said that it is often difficult to secure payment for their treatment. In many cases, workers said they received inadequate care either when the yard owner refused to pay for a certain procedure or simply stopped paying. Some workers received compensation for their injuries, but rarely the full amount required under Bangladesh law. The minimum wage requirements for shipbreaking workers set by the Ministry of Labour and Employment include a monthly stipend for medical care, however, none of the workers interviewed received this stipend.[38]

On June 19, 2019, Sakawat, 28, was carrying an iron bundle on his shoulder when he slipped and the bundle fell, smashing his right foot. He went to Chittagong Medical College hospital where his foot was ultimately amputated. For four weeks he repeatedly requested that the yard owners cover his medical costs, but they refused. He ultimately paid the hospital bills using his entire savings and with loans from his friends. He is now homeless and sleeps at the railway station where he begs for money. He tried filing a case in the local labor court but could not afford the lawyers’ fees so dropped his case.[39]

Sabbir, 27, said that in 2020 he was working as a helper when a piece of iron dropped from the top of the ship and broke his left hand and cut through a tendon. The yard owners took him to the hospital but would only pay for his hand to be bandaged and for some painkillers. He was unable to work for three months and still can hardly grip with his left hand. However, the yard owners did not pay for any additional treatment or any wages while he was out of work, as is required by law.[40]

Rakib, 20, the worker described above who lost his leg and was injured in the stomach by a steel rod, said that when he went to Chittagong Medical College Hospital, the doctors only treated his stomach injury and stopped the bleeding from his leg. He said his mother begged the doctors to fully treat his leg, but the doctors told her that the yard owners were only paying for lifesaving treatment. Rakib was discharged after 17 days in hospital, but after a few days he developed gangrene on his leg. His mother had to take loans to pay for private healthcare, spending $1,000 to treat the gangrene. Rakib and his family have repeatedly sought compensation from the shipyard owners, but he says they have refused to pay anything. “I'm only 20 years old and my life is totally ruined by this accident,” Rakib said.[41]

Sohrab, 25, said that in February 2022 he was carrying an oxygen cylinder when he slipped and the cylinder—weighing about 120kg—fell on his leg and smashed his toes. He said the shipyard owners just gave him painkillers and refused to take him to the hospital. He went on his own to a local clinic where his treatment cost $9 per day, but after ten days he left because he could no longer afford medical care.[42] The day before we interviewed Sohrab, he was working in the yard when a wire pierced his bare foot. He said he did not have enough money to go to the hospital, so he purchased painkillers and pulled the wire out of his own foot.[43]

Nurul, 24, who suffered a spinal cord injury when a heavy piece of iron fell from eight feet and hit him on the back in 2022, said that the yard owner paid some of the hospital bill but eventually stopped. He says he feels severe pain when he lies down or tries to work but he cannot afford pain medication. The company stopped paying his salary as soon as he was injured and never paid any compensation aside from $20 while he was in the hospital.[44]

Some workers, such Asok, 45, took their employer to labor court to cover the cost of treatment. Asok was injured when a heavy piece of iron fell on his back. He said he went to the company office at the yard, but it was closed so he went to the hospital himself. He contacted the yard owners from the hospital asking them to cover the cost of treatment, but they refused. He left the hospital without treatment because he couldn’t afford care. He eventually took the yard owners to labor court, and the court required the owners to cover the treatment cost and to cover half his wages (5,000 BDT (US $50)) for five months.[45] Asok is no longer able to work due to his injuries so now his 18-year-old son is working in the nearby steel rolling mill. “My family is helpless, he said. “We need to survive so I send my son to the steel rolling mill, but my son is also at risk working there.”[46]

Abusive Working Conditions

Bangladesh has laws to protect the rights of workers,[47] but they are seldom properly enforced leading to serious abuses.

No Rest, No Sick-Leave

Workers said they are rarely given breaks or space to safely rest, despite working six days per week in 8-12 hours shifts. Abul, 31, said, “There is no way I can take rest while working for 12 hours. I went to a seminar on workers’ rights where they told us that we should legally have some time and spaces to rest, but in reality that never happens.”[48] Ariful, 28, said that they take a lunch break in the middle of their eight hour shift but otherwise will be reprimanded for resting: “If the foreman or the yard authorities find us sitting or taking rest, they scold,” he said.[49]

Though the 2011 Ship Breaking and Recycling Rules require that shipbreaking yards provide dedicated onsite facilities to take rest, workers say they have nowhere to go. Workers described even trying to rest inside of the ships. Ahmed, 26, said “there is no specific rest room for the workers, we take rest sometimes on the cabin of the broken ships or using the toilet of the broken ships.”[50] Another worker, Mohammed, 39, who has been working in shipbreaking since he was 13, said “There is nowhere to take rest or to eat. When we are working in a ship, we take our foods and snacks on the ship. There is no rest actually.”[51]

A lack of safe rest space is particularly dangerous during night shifts. Syed, 22 said that yard owners provide breaks during night shift but they cannot leave the yard and there is nowhere to safely rest. “When we work at night, we do not get have any safe place to take rest, you cannot just sleep at the yard.”[52]

Workers generally described being given two days of sick leave if they are hospitalized, during which they will still be paid their wages. After two days, wages generally stop, even if the worker is hospitalized due to an injury on the job. Ariful, 28, who had injured his hand lifting heavy iron, explained:

If we have minor injuries, then we have to manage on our own. But if something like amputation type injuries happen then sometimes the yard owner bears the cost, but not in all cases. If I am out of work for more than two days, then they start cutting down the wages.[53]

Faizul, 32, said that in 2021 he cut his leg on a piece of metal wire on the worksite. He said the company paid for basic treatment but that he was paid no wages while he recovered for 15 days at home. He said, “there was no salary for those 15 days because if we don’t go to work, we will get no money.”[54]

Ahmed, 26, said that when he was injured on the job, he lost wages and had to pay for medical treatment:

I was injured four years ago when my veins were cut by some of the scraps. The company provided treatment for only three days. When there was no improvement, I went back home and the company did not even pay wages, let alone cover medical costs.[55]

Lack of Labor Protections

“Shipbreaking workers are usually illiterate and extremely poor, so they just cannot speak for their rights. They are afraid they will lose their jobs,” explained a labor activist. He said that because workers who speak up are frequently fired and they are dependent on those wages to survive, it is difficult for workers to collectively demand their rights.[56]

Denial of fair wages

The Ministry of Labour and Employment set a minimum monthly wage for shipbreaking workers. However, workers are consistently paid far below the required amount.

Human Rights Watch interviewed 23 cutters for this report. On average, their reported monthly wages were 11,564 BDT ($121.72), about half of the minimum wage for ship cutters of approximately 21,250 BDT ($193,67) per month set by the Ministry of Labour and Employment.[57] None of the workers interviewed were receiving monthly stipends for housing, healthcare, and transportation included in the minimum wage total. Helpers we interviewed were earning as little as 5,200 BDT ($54.73) per month— one third of the approximately 16,000 BDT ($145.83) per month that they should be paid according to the minimum wage laws.[58] Helpers were also not being paid the housing, health, and transportation allowances they are owed.

Ariful, 28, who earns 310 BDT ($2.83) per day, said that eight years ago, when he started working as a helper, he earned 290 BDT ($2.64).[59] “We tried to negotiate or protest to raise our wages,” he said, but succeeded in getting only a raise of 20 taka ($0.18).[60] Rashed, a worker and labor rights activist explained:

Workers have no written contracts. This means employers can refuse to pay wages. Employers do not pay the minimum wage announced by the government. Owners just pay according to their will.[61]

Shipbreaking workers are mostly migrants from the impoverished northern part of the country who are employed in the yards through labor contractors.[62] Contractors in this case are other workers who take a commission for bringing in new workers. These arrangements are almost always based solely on a verbal agreement. Once workers are employed in the yard, yard owners will sometimes require them to sign a contract that they were not allowed to read or retain. Asok, 27, explained:

Some companies take signatures from workers only for official purposes. So, when we get our wages, sometimes we have to give our signature but really these “contracts” are not handed over to the workers. Sometimes we sign on a contract paper but also sometimes just a blank piece of paper.[63]

Union-busting

If workers protest conditions or try to unionize, they say they are fired. Kamrul, 39, said “If workers raise their voice, they will lose their jobs.”[64] As Abul, 31, said, “we don’t protest as that might bring retaliation to us.”[65] Syed, 22, said:

No one talks on our behalf. And we do not have any workers union which can fight for our rights like there are so many for the ready-made garment workers. No one works on our behalf or about our rights, even the foreman who are supervising us are also work on behalf of the owners, not for us.[66]

Tanvir, 50, said that he and other workers have been trying to unionize since 1985, but that such organizing is deterred when workers are fired. “When I led a protest against the owner, they fired me from the work,” he said. He filed a lawsuit after being fired but because he didn’t have a contract, the shipyard just claimed he never worked there.[67] Another worker and labor rights activist, Rashed, said that he has been fired more than 30 times from different yards for trying to organize workers.[68]

Activists complained that some of the ship recycling yards have created so-called “yellow unions” that are not genuinely independent, and instead are established by the yard owners to control workers and prevent them from establishing a union of their choice.[69]

A Concealed Industry

Workers say increased scrutiny from journalists and NGOs of conditions in the yards over the past few years has led to a tightening of restrictions on communicating with people outside the yards or providing access to the worksites, and several said that they are not allowed to bring their phones into the yard.[70] Journalists and non-governmental organizations are rarely given access and workers face retaliation for speaking out. Ahmed, 26, said:

If the company finds out that I spoke with you then I will face retaliation and could lose my job. But what I am telling you is true. I don’t know if the ship breaking yard companies will ever think of us as human and provide us with safety equipment. They should understand that if anything happened to us, it is our families who would suffer, not the company.[71]

Another worker, Sohel, 28, explained: “The life of the shipbreaking workers inside the yards or outside always remains hidden because of the pressure of the company owners. If we talk or raise our voice, we will lose our jobs.”[72]

In order to avoid public scrutiny, some yard owners will break ships at night which only increases risk of accidents, despite night operations being prohibited under the 2011 Shipbreaking and Recycling Rules.[73] Dr. Shaheen Chowdhury, law professor at the University of Chittagong, explained that “employers increasingly employ people at night because it is easier to circumvent media and journalists. There is no watchdogging at night. It is a technique to avoid monitoring and surveillance.”[74]

Exposure to Toxics

End-of-life ships are considered toxic waste under the Basel Convention because they are full of toxic materials:[75] asbestos is used as insulation; heavy metals like cadmium, lead, and chromium are in paints and coatings for batteries, motors, generators, and cables; mercury is in thermometers, electrical switches, lights, and often in vessels that have operated in the oil and gas extraction sector; oils, fuel, harmful bacteria, and toxic sludge are found in bilge water,[76] sewage, and ballast water;[77] Polychlorinated Biphenyls (PCBs) are in cables[78]. A 2010 World Bank study projected that between 2010-2030, Bangladesh would import 79,000 tons of asbestos, 240,000 tons of cables containing PCBs, and nearly 70,000 tons of toxic paints via end-of-life ships.[79] Floating Oil Production, Storage and Offloading tankers (FPSO) and Floating Oil Storage and Offloading tankers (FSO) may also contain naturally radioactive substances.

Without proper protective equipment, processes, and storage, handling, and disposal facilities, workers and surrounding communities are exposed to these toxic materials in the air they breathe, the water they drink, and the food they grow and eat.

Airborne pollutants

When workers burn through ships in the cutting phase, toxic chemicals and minerals are released into the air.[80] Without respirators and other recommended protective equipment, workers inhale extremely toxic substances, especially when dismantling inside confined spaces. Tanvir, 50, who works as a cutter, said “When we do the cutting, the smoke gives us respiratory problems like coughing and breathing difficulties. We are not provided any respirators, so we try to use our own clothes as masks but still the smoke gets through.”[81] Faisal, 22, said:

When we cut down oil tanker type vessels sometimes gas leaks from the pipes and we feel sick and have breathing difficulties and sometimes chest pain. This is what work is like for the cutter man. We are bound to work even if those gas emissions cause health problems for us.[82]

Ahmed, 26, said “we need masks, but the foreman never pays any attention to that request. We have to use our t-shirts which we wrap around our mouths as masks.”[83]

Asbestos is one of the most common toxic materials found in older ships. Though the use of asbestos in new ships was banned in 2002, most of the ships coming to Bangladesh for breaking now were built before 2002.[84]

Inhalation can also lead to asbestosis, a form of pulmonary fibrosis (scarring of lung tissues), which causes difficulty breathing.[85] Asbestosis is highly prevalent among shipbreakers in Bangladesh. A 2017 study by the Bangladesh Occupational Safety, Health, and Environment Foundation found that more than one third of the shipbreaking workers surveyed who had worked in shipbreaking for at least ten years were suffering from asbestosis.[86] Asbestosis can lead to cardiovascular disease as a result of severely decreased lung capacity and significantly increases risk of mesothelioma and lung cancer.[87]

Nazmul, 51, who works as a cutter and is an advocate for shipbreaking workers’ rights said that he knows 33 workers with asbestosis, himself included. He said he suffers from chest pain and shortness of breath, and that four of his colleagues have died from complications related to asbestos exposure.[88] In a focus group discussion with 15 shipbreaking workers with asbestosis, all of the participants described experiencing chest pain, physical weakness, breathing problems, and difficulty doing day-to-day tasks.[89] Imran, 59, said “I cannot go upstairs, I am deteriorating day by day.”[90]

Dr. Rajat Biswas, an internist and assistant professor in the Department of Medicine at Chattogram Maa-O-Shishu Hospital Medical College explained that out of his 16 current patients who are shipbreaking workers, 15 are suffering from respiratory conditions—mostly asbestosis—often requiring a nebulizer to help them breathe (an inhaler that delivers medication).

The medicine and Inhaler required to ease symptoms costs about 11,000 BDT per month (US$118), but workers say their employers have refused to cover medical costs, despite their legal obligation to do so under the Bangladesh Shipbreaking and Recycling Rules, 2011 and the mandated medical stipend included in the minimum wage legislation for shipbreaking workers.[91] Some workers suffering from asbestosis have formed an Asbestos Victims Rights Network and have held seminars and a peaceful protest calling on their employers to pay for the treatment and lost wages related to the disease, but they have received no response. Arif said, “Since the asbestosis diagnosis I feel scared all the time. I need medicine and I need money.”[92]

Some former workers with asbestosis said they were no longer able to work because it was too difficult to breathe and maintain stamina. As a result, their children had to drop out of school to help make ends meet. Ali, 42, said that his 16-year-old daughter had to leave school to work in a garment factory. “She was a student, but her education stopped now because I cannot work,” he said.[93]

Asbestosis is almost entirely preventable with adequate safety procedures and protection equipment.[94] But as Dr. Biswas said, “They need a better environment, better awareness,” he said. “They don’t know the toxins they are exposed to, how to prevent exposure. They are untrained. What they have learned has been on the spot.”[95]

Having proper procedures in place to handle and dispose of asbestos is critical.[96] One ship recycling expert explained that “rules and regulations within the EU concerning the management, removal, and disposal of asbestos products are very strict. Removal can only be done by specialized licensed companies, asbestos waste has to be double bagged and can only be transported in closed and sealed containers, disposal can be glazing or mixing with concrete to permanently fix the fibers.” [97]

According to the 2011 Bangladesh Ship Breaking and Recycling Rules, all shipyards are required to have an asbestos storage unit on site[98] and workers must be provided with equipment for the safe removal of asbestos.[99] Yards are required to remove asbestos in leakproof containers and dispose of it according to regulations set by the Department of Environment.[100] But these procedures are rarely followed. Instead, workers and experts say the asbestos is just sold in the local market in what some workers called “asbestos villages.”[101] Asbestos from ships is used in cooking stoves and other furniture for sale. “The way they are breaking it and transporting it to different shops is a whole mess,” one Bangladeshi activist said. “They just take it from the ship and bring to the shops.”[102]

Soil and Water Pollution

Studies over the last decade have found that heavy metals such as iron, manganese, cobalt, copper, zinc, lead, cadmium, nickel, and mercury released from the ships on Bangladesh’s shores are contaminating the soil and groundwater, and via these, local fruits and vegetables.[103] For example, a 2020 study by researchers from the Bangladesh Council of Scientific and Industrial Research measured the metal contamination of soil around shipbreaking areas and food crops grown nearby and found that some crops were so heavily contaminated with dangerous heavy metals that they exceeded the threshold set by the World Health Organization for safe consumption.[104] The researchers estimated that copper, zinc, cadmium, and lead are “contributing to the potential human health risk in the ship breaking area.”[105]

Cadmium is carcinogenic and exposure through drinking water can result in neurodegeneration and other diseases.[106] When workers breathe in cadmium through industrial dust, exposure can lead to kidney damage and lung injuries.[107] Exposure to chromium can lead to neurological diseases and several cancers.[108] Mercury, when exposed through inhalation, ingestion, or skin contact, attacks the nervous system and can result in lifelong disability and even death in higher doses. Mercury is typically absorbed into the surface of a ship’s carbon steel tank walls, piping, and pumps and is frequently found in oil extraction ships. When heated up by simple methods such as sand blasting, water blasting, grinding, and gas-axing (such as the oxygen-acetylene torches used by ship cutters), extremely toxic mercury vapor is released in high concentrations which will bypass most commercial personal protection equipment. Children are particularly susceptible to the harms of mercury poisoning because their bodies are still developing, meaning children working in shipbreaking yards are at particular risk. There is no known safe level of exposure.[109]

Additional Environmental Impacts

Without the use of dry-docks it is nearly impossible for shipyards to deploy the proper tools and containment measures to safely process toxic ships. In 2010, Calin Georgescu, the then special rapporteur on toxics and human rights, argued that the requirement under the Basel Convention to take all practical steps towards the “environmentally sound management” of hazardous wastes “cannot be achieved when ships are dismantled on tidal beaches without concrete covering or any other containment.”[110]

At time of writing, Bangladesh does not have a toxic waste storage, treatment, and disposal facility for shipbreaking, despite commitments under the 2018 Ship Recycling Act to build one by 2021. Because ships in Bangladesh are broken down directly on the beach, toxic waste is dumped straight on the beach and the sea. Because Bangladesh is situated on a delta, the coasts have some of the largest tidal ranges in the world, meaning some toxic substances are swept out to sea and then back inland up coastal waterways.[111]

Asok, 45, who has worked in shipbreaking since he was 10 years old, said that in recent years the shipyard owners created some storage rooms for waste, but that “actually they are throwing that waste into the sea. That’s why the sea water is getting polluted. And when investigators come to the yard that’s the only time waste is taken to the rooms.”[112]

Pollutants are permanently impacting marine biodiversity and coastal habitats. According to the Marine Institute of the University of Chittagong, the shipbreaking industry has wiped out 21 species of fish and crustacean and endangered 11 other species.[113]

A 2017 study by researchers at Bangladesh’s Jahangirnagar University estimated that there are about 20,000 fishing families living along the Sitakunda coastal strip whose lives and livelihoods are threatened by the pollution from shipbreaking. Fishermen explain that not only are the fish they rely on for their livelihood disappearing, but incoming boats regularly tear through their nets which take months to repair, cutting into an important source of income.[114]

Aijaz, 25, said that he used to be a fisherman but started working in shipbreaking because ships kept breaking through his nets. He explained:

When a ship is taken to the yards the propeller tears the nets of the fishermen. But whenever fishermen go to the yard owners asking for compensation for their nets, they scold them and do not give them taka for their losses. Water is polluted by the ship when they throw the fuel and chemicals in the water that is harmful for the sea plants and fish. Fishermen are not getting fish as they got before. There is a scarcity of fishes in the coastal areas here.[115]

Masum, 44, who started selling fish after he was injured in the shipbreaking yards said “the sea water is being polluted by the ships and it is poisonous in the sea water, so the fisherman are not finding any fish. The fish are dying. That’s why fishermen have to go into the deep sea to catch fish. Lives of the fishermen are getting risky day by day.”[116]

Nurul, 24, explained that not only do shipyard owners refuse to pay for the fishermen’s losses when ships break through their nets, but they also will threaten and intimidate the fishermen. “Sometimes the yard owners confiscate the nets to prevent fishing. The owners feel it gets in the way because they want to control the beach area. The fishermen can’t say anything because shipyard owners are powerful and fishermen are very poor.”[117]

The shipbreaking industry is also responsible for cutting down coastal mangrove forests, one of Bangladesh’s most important lines of defense against climate change. Bangladesh is one of the most vulnerable countries to climate change in the world. It is predicted that in the next 30 years more than 10 percent of coastal land will disappear, displacing one in seven people.[118] Mangrove forests serve as an important barrier to erosion, holding land together with their roots as tides rise.[119] However, shipyard owners have illegally cut down swaths of mangroves to make way for incoming ships.[120]

II. Legal Framework for Ship Recycling

There are international and national laws and guidelines for safe and environmentally sound ship recycling. However, these requirements are frequently ignored or circumvented. Without effective enforcement, Bangladeshis will continue to pay the heavy cost in the form of damage to the environment, to health, and to the rights of workers.

International and National Rights Obligations

Right to Safe and Healthy Working Conditions

The International Covenant on Economic, Social, and Cultural Rights (ICESCR), ratified by Bangladesh, requires all party states to ensure safe and healthy working conditions.[121] The International Labour Organization additionally lays out obligations and standards to protect worker’s rights to occupational health and safety. The two core instruments are the Occupational Safety and Health Convention (C155) and the Promotional Framework for Occupational Safety and Health Convention, 2006 (C187). In June 2022, ILO delegates voted to add the principle of a safe and healthy working environment to the Fundamental Principles and Rights at Work, meaning that all ILO Member States are committed to respecting and promoting the fundamental right to a safe and healthy working environment, regardless of whether they have ratified the relevant conventions.[122] Though Bangladesh has not ratified ILO Conventions 155 and 187, it is therefore still obligated to uphold their standards.

Nationally, there are three main pieces of legislation protecting shipbreaking workers’ rights to occupational health and safety: the 2011 Shipbreaking and Recycling Rules (enforced through the 2018 Ship Recycling Act), the 2013 National Occupational Safety and Health (OSH) Policy, and the 2006 Labour Act.

The 2011 Shipbreaking and Recycling Rules require that all workers are provided with personal protective equipment including head, face, hand, and foot protection, respiratory protective equipment, hearing protection, protection against radioactive contamination, protection from falls, and appropriate clothing meeting standards set by the Bangladesh Standards and Testing Institution under the Ministry of Industries.[123] Yards must have systems and procedures in place to document and track all hazardous waste on ships and to adequately respond in case of emergency. The rules also explicitly call for yards to establish an occupational health and safety policy in consultation with workers.[124]

The 2013 OSH Policy applies to all workplaces, formal and informal, including shipbreaking yards, and requires employers to provide training, guidelines, and adequate safety equipment.[125] It also recommends periodic medical examinations of workers to identify potential workplace-related diseases or injuries.[126]

The Bangladesh Labour Act 2006 (amended in 2018) states that “no authority shall engage any worker in work without providing him with personal safety equipment,”[127] including safety goggles in conditions where they are at risk of exposure to excessive heat, debris, or light, as is the case for shipbreakers.[128] The law prohibits work requiring people to lift, carry, or move excessive weight that would be likely to cause injury. The law also requires employers to maintain safety records in any facility employing more than 25 workers.[129] If a worker reports an injury, the employer is required within three days of such notice, to “ensure the worker is examined at the expense of the employer by a registered medical practitioner.”[130] In the case of a fatal accident, employers are obligated under the Labour Act to report the accident within seven days to the local Labor Court.[131] The employer is liable to pay compensation if the worker suffers “total or partial disablement” for more than three days.[132] Injuries eligible for compensation include occupational diseases specific to the employment context such as asbestosis and certain cancers in the case of shipbreaking.[133]

Under the Fatal Accidents Act, 1855, in the case that a worker dies in a workplace accident, the court may pay damages to the family “proportioned to the loss resulting from such death.”[134] The Labour Welfare Foundation Act, 2006, set up a workers’ welfare foundation called the Bangladesh Sramik Kalyan Foundation (BSKF).[135] The BSKF’s responsibilities include providing financial assistance to workers who are physically disabled, arranging medical treatment and providing financial assistance to workers in case of work-related injury, and providing aid to the worker’s family in case of death.[136]

Right to Health

The International Covenant on Economic, Social and Cultural Rights (ICESCR), which Bangladesh ratified in 1998, specifies that every person has a right “to the enjoyment of the highest attainable standard of physical and mental health.”[137] Because states have different levels of resources, international law does not mandate the kind of health care to be provided beyond a certain minimum level. The right to health is considered a right of “progressive realization,” meaning that by becoming party to the ICESCR, a state agrees “to take steps … to the maximum of its available resources” to achieve the full realization of the right to health.[138]

The ICESCR requires that states, in order to realize the right to the highest attainable standard of health, shall take the steps necessary for “the improvement of all aspects of environmental and industrial hygiene.”[139] The Committee on Economic, Social, and Cultural Rights (CESCR) which interprets and monitors states’ compliance with the ICESCR in the General Comment 14 on the Right to Health, has interpreted the ICESCR to include:

… [T] he prevention and reduction of the population’s exposure to harmful substances such as radiation and harmful chemicals or other detrimental environmental conditions that directly or indirectly impact upon human health.[140]

The right to health encompasses the right to healthy natural environments.[141] The CESCR has explained that governments violate the right to the highest attainable standard of health if they fail to regulate the activities of corporations to prevent them from violating the right to health of others.[142]

Labor Rights

Both the ICCPR and the ICESCR, along with the relevant International Labour Organization (ILO) conventions, guarantee the right to join trade unions. These, together with the authoritative interpretation of the ILO core conventions overseen by the ILO Committee on Freedom of Association (CFA), obligate governments to ensure that employers do not thwart union formation and participation.[143]

ILO Convention No. 87 provides that workers have the right to join organizations “of their choosing without prior authorization” and authorities should not engage in any interference that would restrict this right or impede its enjoyment.[144] ILO convention No. 98 provides that workers shall be protected from anti-union discrimination, in particular acts to “cause the dismissal of or otherwise prejudice a worker by reason of union membership or because of participation in union activities outside working hours or, with the consent of the employer, within working hours.”[145] Bangladesh has ratified ILO conventions 87 and 98 on freedom of association and collective bargaining, and is required to protect the rights contained in them.

Section 195 of the Bangladesh Labor Act (2006, amended 2013) makes it illegal to “dismiss, discharge, remove from employment, or threaten to dismiss, discharge, or remove from employment a worker, or injure or threaten to injure him in respect of his employment by reason that the worker is or proposes to become, or seeks to persuade any other person to become, a member or officer of a trade union.”[146]

Working Hours and the Right to Rest

The ICESCR requires all party states to ensure rest, leisure, and reasonable limitations of working hours.[147] Under the Bangladesh Labour Act 2006, workers should not regularly work more than eight-hour days.[148] Employers are required to allow one hour rest or two half hour intervals in an eight-hour workday.[149] Under the Bangladesh Labour Act, 2006, every worker is entitled to sick leave with full wages for 14 days in a calendar year.[150]

Wages

Though a living wage is not nominally defined under international law, Article 23 of the Universal Declaration of Human Rights states that “everyone who works has the right to just and favourable remuneration ensuring for himself and his family an existence worthy of human dignity, and supplemented, if necessary, by other means of social protection.”[151] The International Labour Organization enshrines this right in Conventions 95 and 131 and includes recommendations on enforcing minimum wages, including by protecting the right to freedom of association.

The ICESCR recognizes the right to a remuneration that provides for “a decent living for themselves and their families” in accordance with other basic rights protected by the covenant.[152]

In 2018 the Ministry of Labor and Employment established minimum wage requirements in the shipbreaking sector under the 2006 Labour Act. Most of the workers interviewed for this report fall under either Grade three (cutters) or four (helpers). According to the requirements, employers must pay those in Grade three 21,250 BDT ($194) per month, including stipends for housing, medical care, and transport.[153] For Grade four, employers must pay 16,000 BDT ($146) per month, including stipends for housing, medical care, and transport.[154] Many Bangladesh shipbreaking companies do not comply with these minimum standards, instead offering contracts that workers sign for a fraction of the wages without any effort at informed consent.

Child labor

The Bangladesh government has identified shipbreaking as one of 38 most dangerous forms of child labor as part of its 2008 National Elimination of Child Labour Policy.[155] The 2009 High Court 18-point directive bans the employment of children under the age of 16 in shipbreaking yards and the 2011 Shipbreaking and Recycling Rules ban the employment of children.[156] Still, researchers estimate that 13 percent of shipbreaking workers overall are children and that 20 percent of workers during illegal nightshifts are children.[157]

The UN Convention on the Rights of the Child and the ILO Worst Forms of Child Labour Convention, both ratified by Bangladesh in 1990 and 2001 respectively, require states to ensure companies are prohibited from employing children under 18 in work that is likely to be hazardous or harmful, or to interfere with the child’s education.[158]

The Worst Forms of Child Labor Recommendation provides guidance to countries on determining what types of work constitute harmful or hazardous work.[159] Many of these conditions are present in the shipbreaking industry such as work at dangerous heights or in confined spaces, work with dangerous machinery, equipment, and tools, and the manual handling or transport of heavy loads; unhealthy environment “which may, for example, expose children to hazardous substances, agents, or processes, or to temperatures, noise levels, or vibrations damaging to their health;” and work during night shifts.[160]

International Laws and Regulations on Hazardous Waste and Ship Recycling

While existing international regulations lay out parameters for safe and environmentally sustainable ship recycling practices, they currently fail to address loopholes that prevent effective enforcement.

The Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and their Disposal (the Basel Convention)

Adopted in 1989 by the United Nations Environmental Program (UNEP), the Basel Convention restricts and regulates the international trade of hazardous waste and requires state parties to “take all practical steps to ensure that hazardous wastes and other wastes are managed in a manner that will protect human health and the environment from the adverse effects which may result from such wastes.”[161]

Under the Basel Convention and the Basel Ban Amendment, the country of the ship’s port where it is declared waste is obligated to ensure that the receiving country has sufficient capacity for environmentally sustainable management of toxic waste.[162] Exporting countries are also obligated under the Basel Convention to obtain prior informed consent from the importing country which includes providing documentation of hazardous materials in the ship. [163]

In 2002, the Basel Convention Secretariat adopted the Technical Guidelines for the Environmentally Sound Management of the Full and Partial Dismantling of Ships (the Basel Convention Technical Guidelines) to serve as benchmarks for states to meet their obligations under the convention. According to the guidelines, state parties were expected to upgrade existing shipbreaking facilities to meet the standards of the model facility outlined in the technical guidelines within ten years of their adoption (by December 2012).

Our interviews suggest that twenty years since the adoption of the Basel Convention Technical Guidelines, shipyards in Bangladesh have yet to fulfill even the first stage of improvement.

|

The standards outlined in the Basel Convention Technical Guidelines[164] include: |

|

Within one year of adoption (as of December 2003): - Requiring inventories, cleaning, and safe removal of hazardous substances before recycling. - Facilities should provide clean sufficient work areas with clearly demarcated zones for work, provide personnel with adequate protective equipment, and implement training on safe shipbreaking practices according to agreed-upon standards.[165] Within five years of adoption (as of December 2007): - Facilities should have implemented basic measures of an Environmental Management System[166] including a waste management plan, a contingency preparedness plan, and a monitoring plan for the safe and environmentally sound management of shipbreaking waste. Within ten years (as of December 2012): - Facilities should have full containment measures in place and ships should be deconstructed on impermeable floors (e.g., using a dry dock or pier). - All asbestos should be removed using a vacuum decontamination unit. - Incineration or landfills should have adequate environmental protections. - All facilities should use a functioning wastewater treatment system. - All facilities should be certified according to generally accepted standards.[167] |

The Basel Ban Amendment

In 1995 a group of developing countries created the Basel Ban Amendment, which builds on the Convention and prohibits the export of hazardous wastes from member states of the European Union, Organization for Economic Cooperation and Development (OECD), and Liechtenstein to all other countries. The Ban Amendment entered into force on December 5, 2019.[168]